#Pre-Printed label manufacturers

Explore tagged Tumblr posts

Text

Discover the Best Label Manufacturers for Your Business Needs with Barspell Technology

In today's fast-paced business environment, the demand for high-quality labels is at an all-time high. Whether you're looking for pre-printed label manufacturers or a barcode label manufacturer, finding the right supplier can make all the difference in ensuring your products are well-branded and easily identifiable. At Barspell Technology, we specialize in providing top-tier label solutions that cater to various business needs, enhancing both efficiency and branding. This article delves into the importance of labels, the different types of label manufacturers, and how Barspell Technology can help you choose the best supplier for your specific requirements.

Why Labels Matter: An Overview

Labels are not just for identification; they play a vital role in marketing, branding, and logistics. From barcode labels used for inventory tracking to pre-printed labels that showcase your brand, choosing the right label manufacturer can enhance product presentation, improve supply chain management, and streamline operations. Whether you are in retail, manufacturing, or e-commerce, the quality and design of your labels can influence both customer perception and operational efficiency. Barspell Technology is committed to delivering high-quality, durable labels that help businesses like yours thrive.

What to Look for in Label Manufacturers

When searching for the best label manufacturers, several factors should be taken into consideration. Quality, durability, customization options, and cost-effectiveness are crucial for any business, regardless of industry. A reliable label manufacturer, such as Barspell Technology, will offer:

1. Customization Options: Labels can be tailored to fit the specific needs of your products, whether it’s pre-printed or featuring barcode technology.

2. Durability: High-quality labels that withstand various environmental conditions, from heat to moisture, are essential for long-term product labeling.

3. Fast Turnaround Times: Depending on the urgency of your business needs, Barspell Technology provides quick and efficient label production services.

4. Competitive Pricing: Choose manufacturers that offer a good balance of quality and cost, providing you with value for money.

Pre-Printed Label Manufacturers: Streamlining the Process with Barspell Technology

For many businesses, pre-printed label manufacturers offer a simple solution for efficient labeling. These labels come with your design already printed, which can save time in your production process. Pre-printed labels are ideal for products that have fixed information, such as barcodes, ingredients, or brand logos.

By working with experienced pre-printed label manufacturers like Barspell Technology, you ensure that each label is consistent, professionally designed, and printed with high-quality materials that can withstand wear and tear.

Barcode Label Manufacturers: Essential for Inventory and Logistics

Barcode labels are essential for inventory control, shipping logistics, and point-of-sale systems. A barcode label manufacturer such as Barspell Technology can provide you with high-quality labels that are scannable, durable, and customized to fit your product's needs. These labels enable fast, accurate tracking of products throughout the supply chain, which can significantly reduce human error and improve efficiency.

Whether you need standard 1D or advanced 2D barcode labels, Barspell Technology ensures that your barcodes are printed, scannable, and resistant to fading, ensuring smooth operations.

Choosing the Right Label Manufacturer for Your Business

With so many options available, choosing the right label manufacturer can feel overwhelming. Here are a few tips to help you make an informed decision:

1. Reputation and Reviews: Look for manufacturers with a proven track record of delivering high-quality labels. Barspell Technology has earned a reputation for quality and customer satisfaction in the labeling industry.

2. Industry Experience: A manufacturer experienced in your industry will understand your unique labeling needs and offer expert advice.

3. Technological Capabilities: Ensure the manufacturer uses the latest printing technology to deliver precise, high-quality labels. At Barspell Technology, we leverage cutting-edge technology to provide labels that meet your exact specifications.

Conclusion: Find Your Perfect Label Manufacturer with Barspell Technology

Whether you're looking for barcode label manufacturers or pre-printed label manufacturers, it’s important to work with a company that understands the nuances of labeling and meets your business’s unique requirements. By considering factors such as customization options, quality, and industry experience, you can find a label supplier to support your product labeling needs and help streamline your operations.

Labels are more than just a necessity they are an essential part of your brand’s identity and functionality. Partnering with Barspell Technology ensures you get the best labels to elevate your brand and optimize your business processes.

1 note

·

View note

Note

I love your art so much!!! I've also been starting to paint with gouache, and I'd love to know a little more about your process! What kind of paints do you use, do you sketch first or start with paint, do you paint in layers over several day or all at once?

Hi and thank you! I hope you don't mind me answering this publicly and apologies for length, but:

MY ART PROCESS!

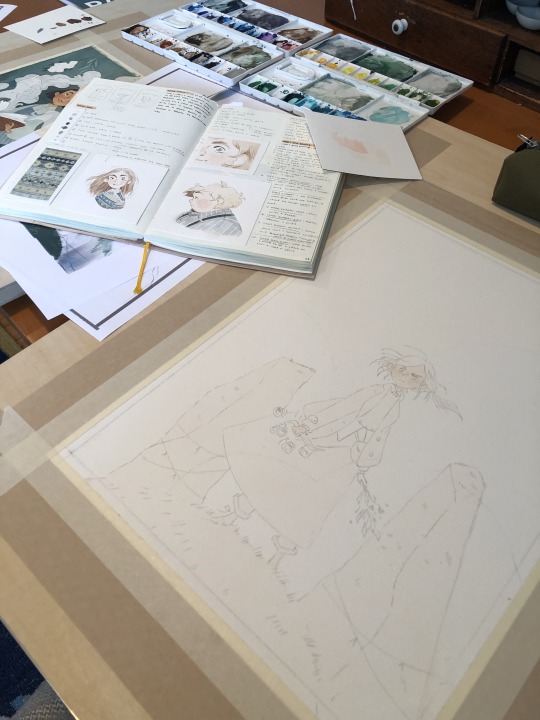

Supplies: I use winsor and newton gouache and arches cold press paper blocks, usually 140 lbs (the lime green ones) and sometimes 300 lbs (the teal green ones). Even though this paper comes pre-stretched in blocks, I actually take the sheets off and stretch them myself because I've found arches' glue isn't as strong as it used to be. This is how you get watercolor paper to lay flat! I recommend youtubing some videos on how to do it -- there's a lot of great tutorials out there. Also, I use princeton brushes, and kraft paper tape and these boards to stretch my paper. (these aren't affiliate links, I just shop at blick)

A word about art supplies: these are the exact tools I use but everyone uses supplies differently and two people with the exact same supplies might get different results! A lot of it is about what works for you and what you like, so I always suggest that gouache/watercolor beginners just buy a few tubes from a couple of different paint companies and some small pieces of paper from different manufacturers to see what you like. Just changing one ingredient in the above has created massively different results for me, but maybe that'll end up being something you'd like! The first step in learning a new medium imo is to play. Just have fun!

ALSO: gouache isn't super light permanent, check your tubes for which ones hold up to sunlight. Here is winsor and newton's color chart explaining which ones will fade when exposed to sunlight -- all manufacturers will give you this. I only use the colors rated A and AA, and I still frame my pieces with UV glass just to be safe. Not all gouache is re-wettable, but winsor and newton is. I just put it in my palettes and refill my palettes if it runs low. AND SOME PAINT IS TOXIC. A lot of paints have cadmium and cobalt in them. I don't use any of the toxic colors, but if you do, make sure you don't eat while working and wash your hands thoroughly afterwards. This information is also usually available on manufacturer's websites. As more people are rejecting cadmium paint, you'll see more tubes labeled things like cadmium-free yellow. This is why. More artists should be aware that their tools can be dangerous. You don't need that many tubes of paint to begin, just a warm and cool red, warm and cool yellow, warm and cool blue, white and black. I have around 50 colors and use 20 regularly. I always mix all my colors myself, and never use straight tube paint. Most of my colors have about 5-6 different tube colors mixed together. If you use re-wettable paint a tube of paint will last you years; even as a professional I only buy new paints every 5 years or so.

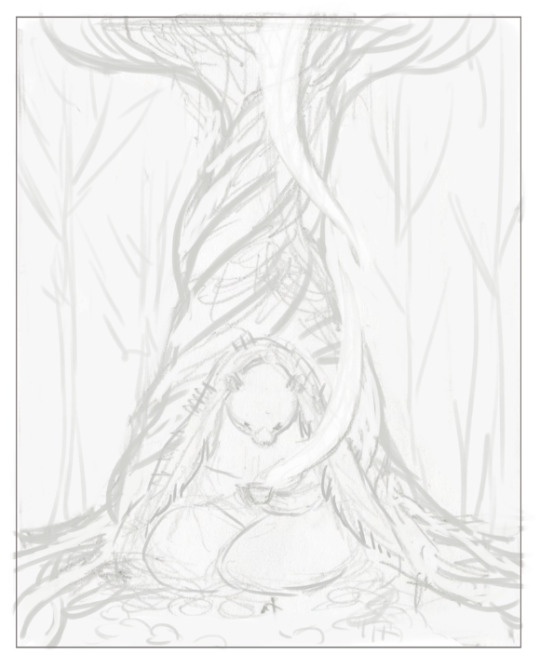

Process: I ALWAYS start with a sketch first. Not everyone has to, but because I do illustration work -- where sometimes a client gets input on a drawing -- I always do a lot of preliminary work before I even begin to paint. At this point, even my personal work usually involves the exact same process:

I start with a 3" or so thumbnail that I scan (left; I traced it quickly digtally for clarity to myself here) and then either clean up digitally or print out and clean up traditionally with tracing paper (right):

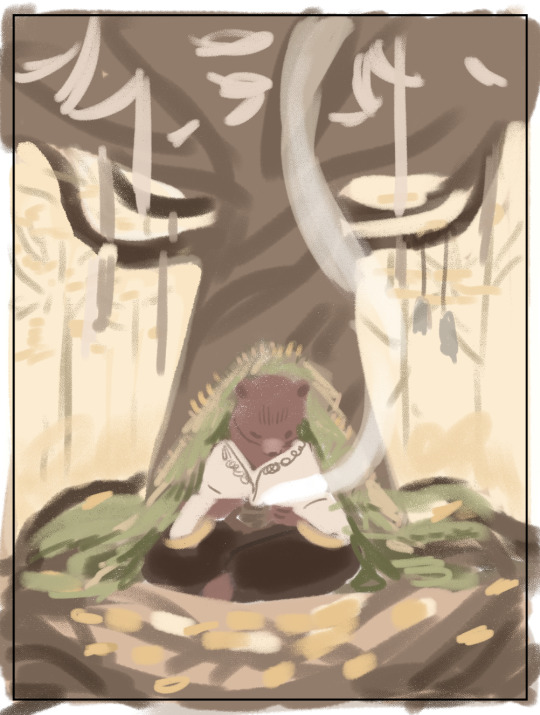

Then I scan the cleaned sketch in and color rough it digitally (left, this was for a gallery show, so no one had to approve my color roughs, so it's messy!) then I transfer my sketch to my paper (with either carbon transfer paper or a light table), stretch my paper, and paint (right):

I obviously changed my mind about the color of the ribbon in the trees, ha, and made everything a lot more vibrant. The benefit again of gallery work is no pre-approval!

You are correct, I paint in a series of washes, going from lightest to darkest, where I apply the same color beneath all shapes that are the same warmth (cools under all upcoming cools, warms under all upcoming warms). I paint a piece usually in one or two days, depending on complexity. I didn't take pictures of the above painting, but here's a different painting to show you a little bit what I mean:

I painted the peach color under everything (and twice for skin tones), and the gray color of the sky under everything that would be grayish (the rocks, trees, her pants, her skirt, and coat). I do this to stop me from getting darker lines where two different colors butt up against each other, and also for color harmony. I have step by step photos of this in my process stories highlight on my instagram; also check my FAQ and tip highlights for more info on all this stuff. Most pieces take around 25-30 washes before I start adding in the details (sometimes I add in face details early though because if I mess those up it's not worth finishing the rest of the painting! 😅)

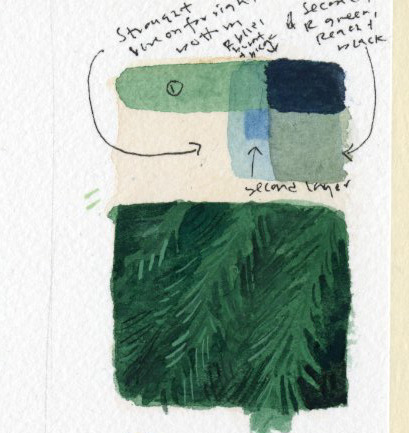

All this might seem like a lot of work (...it is) but I do it so that I can show clients previews of the final piece and so I don't have to repaint the finals. I also used to pre-test all of my washes on scrap paper like this:

I still recommend doing this if you're just beginning! But at this point I only do it when testing techniques because I know my paints really well. (the above was my test for the pine boughs in this piece)

Painting by far is the longest part of the process, so I do more work up front to not have to do it twice. Every piece takes about 6-24 hrs of actual work time to produce. Stretching watercolor paper takes about 24 hrs to dry, and because I sell most of my originals in galleries, they need to be flawless, so planning ahead is useful and in the end saves me time.

And to conclude this novel of an explanation, don't be overwhelmed by all the information I've given you! I put it here so that people at various stages of their artistic journey can maybe find something useful in it. But seriously, the first step to learning how to paint whether it's traditionally or digitally is just to have fun. Try it out, see what's working and what isn't, and then try to solve specific issues that you're struggling with. I've been doing this for a loooooong time at this point, but here's my first watercolor piece from when I was re-teaching myself how to paint traditionally nine years ago:

Obviously, I was destined for greatness. Ha, yeah, no. If you scroll back through my tumblr archive, you can see me learning how to use these paints in real time. And keep in mind that I'd been working digitally for years before then, and years before that where I didn't post my work online at all.

So for anyone who needs to hear it: there's no such thing as talent, just hard work, patience, and trying again and again and again...and sometimes again. What I do is a skill and anyone can learn it. Sometimes, progress is slow. I'm 38. I only really feel like my art was half-way decent starting a few years ago, but I've been making art my entire life, and I went to art school at 18. 20 years later I'm kind of figuring it out.

The best advice I can give, whether it's about art or not, is find the thing you love so much that you'll keep at it even when you suck at it, because most skills you'll suck at to begin with -- and perhaps for a long time. I sucked at art for yeeeaaaaarrrrs. On top of the usual learning curve, I struggled with fine motor control and dexterity. But I loved it so much I kept trying every time I failed. If I can do it, so can all of you, no matter what stage of art you're at now, and no matter how old you are.

Anyway, thank you to those still reading this deep in. I wish you all the best on your artistic journey. Art can kick your butt sometimes, but it's also pretty dang rewarding 💛

536 notes

·

View notes

Note

If you don't mind me asking, what do you use to print and cut your sticker?

Or get your charms made?

They all look so cute!

it's no problem! for stickers, i print them on "online labels" sticker paper at home with my home printer, laminate them (for more waterproof protection and/or pretty effects, depending on what i use) with laminating sheets and/or glitter sheets, and then cut them out with my silhouette cameo 3 i got pre-owned from ebay bid snipping

as for charms, i use vograce; it's a very good manufacturer, especially for beginners. there's a lot of tutorials that can be watched online for help; that's what i did! just have to search what Specifically you want to know, like looking up shaker charm video guides for shaker charms you want to make, etc etc

overall it's a lot of diy stuff to have fun making stuff for yourself and others if you have the resources and drive to do, ty for asking!

7 notes

·

View notes

Note

I have a question about IRL merch — did their clothing used to be better quality and it has gotten worse, or is it just the calendars that were worse this year? I ask bc I just got a shirt and sweatshirt from another content creator for the Same Price as dnp merch and the difference between them is crazy. Like I don’t think the dnp clothing feels cheap or whatever but the other merch just has a much thicker fabric and the sweatshirt is much softer on the inside. I don’t buy a lot of content creator merch in general so I’m not sure which of these is the norm for clothing quality!

(everything i have pre-crafts merch is UK manufactured and shipped)

i'd say it got worse overall. i am biased, though. they switch from one t-shirt company to another all the time, the same with longsleeves and hoodies. sometimes the material quality is good, sometimes it's sooo thin 🥲

the printing quality is inconsistent now, but idk how it was before 2022, not because i don't have older merch (i do), but because i haven't asked anyone and weren't paying much attention back then.

i also wanna point out that sometime around WAD (could be earlier) they stopped making their own branded labels*. Dan's "don't talk to me" longsleeve has DH label, but then... WAD doesn't (which can be understandable; the marble ii shirt also doesn't, but ii longsleeve does have printed D&P "label"), and all merch after their comeback has the original label of the company where they bought it. it's not about quality, i understand that, i just wanted to point out that they stopped making their merch more unique (i guess, i could call it that). i get that it's cheaper for them to not touch labels, but like, some old merch is just... cute. the new one? basic. for the same price!

*WAD leather jacket has a customized label - the only item. but the jacket itself was custom-made, i guess, so i'm not surprised.

i remember when dnp were selling candles, the shipping wasn't organised well enough and i knew people who got their candles broken. and someone told me that there was a problem with Phil's hot chocolate at the customs in one of Latam countries. dare i say, it wasn't handled correctly by IRL Merch (no chocolate, no refund in the end). all of that was pre-WAD. again, not the merch quality, per se, sorry.

4 notes

·

View notes

Text

Improving printing sustainability with digital technology

Environmental sustainability is increasingly a board-level agenda, with supply chain sustainability – including the impact of printing – a key factor for manufacturers and brands. The impact of this scrutiny extends to suppliers, who in turn must be able to demonstrate their efforts to reduce their environmental impact.

For converters, achieving sustainable practices can be challenging, as packaging and label creation can consume much energy and water while producing avoidable waste.

Modern digital printing technology can help. Michael Matthews, product manager – DP Colour, Domino, explains how converters can reduce the environmental impact of packaging and label creation, supporting their and their brand customers’ sustainability objectives.

From ‘forecast’ to ‘print on demand’

A traditional ‘forecast demand’ printing model has long been preferred for cost-effective flexographic printing of established, high-volume SKUs. However, changing consumer demand has seen an increase in more limited product runs, including seasonal and promotional releases. The consequence for converters can be unpredictable packaging volumes, with brands preferring to opt for smaller quantities of packaging to mitigate waste while the product is being proven.

Managing shorter print runs can be challenging for flexo converters, considering the cost of creating printing plates, time-consuming press set-up, and set-up waste. Adding digital printing capability to flexo presses to create a hybrid line, or investing in a digital roll-to-roll press alongside established flexo lines could help converters adopt a more sustainable ‘print-on-demand’ business model for shorter run packaging.

Digital printing for sustainability

With digital printing technology, used roll-to-roll or as part of a hybrid printing process, converters can offer an entirely new business model to their brand customers, with the ability to deliver short-run or variable product packaging while cutting costs and reducing waste.

Reducing avoidable print waste saves both converters and brands money and reduces the need to handle excess printed stock. Energy used in the transport and recycling processes for excess stock will contribute to a brand’s overall carbon emissions. In addition, large volumes of water and chemicals are often used to de-ink excess stock for recycling, with a risk of pollution if items are handled incorrectly.

Reducing print waste

Print waste encompasses much more than printed packaging that must be discarded due to overstock and obsolescence. Digital printing technology offers several opportunities for converters to lower the environmental impact of their operation, including ways to improve the environmental performance of flexo processes as part of a hybrid process:

Print-on-demand

Print-on-demand eliminates minimum order quantities and prevents overrun, saving energy, reducing ink and substrate use, and lowering the need for transporting and recycling excess stock.

Late-stage customization

With late-stage customization, finishing touches are added to pre-printed stock at the manufacturer’s facility. The packaging design is printed in bulk by a converter, and details requiring frequent updates, such as promotional content or variable data, are added shortly before or during the packaging process, helping to reduce obsolescence.

Plate-free printing

Plates and analog pre-press waste – such as ink and media used during set-up and proofing – can account for more than 10% of a brand’s annual spend, depending on the number of SKUs and variations produced. Reducing or eliminating the use of plates helps minimize water consumption, ink waste, and chemical waste during plate cleaning, and the need to treat contaminated wastewater.

Efficiency by design

The precise drop placement of digital inkjet printheads means that digital inkjet presses only use the amount of ink needed to create the label design, without residual ink on analog plates going to waste at job changeover.

Onboard automation of maintenance tasks, such as printhead cleaning and constant ink circulation, can help ensure reliable, efficient performance while reducing overall consumables use.

In addition, the high-efficiency drying technology featured in modern digital inkjet labels and corrugated presses typically uses fewer pinning and curing lamps versus flexo processes, delivering further energy savings. The overall reduction in consumables and energy use during press usage can contribute to a reduction in carbon emissions across the supply chain, as well as offer cost savings.

Workflow optimization

In digital printing, automating the pre-press workflow via digital front-end software enables digital proofing, saving time and additional waste from hard proofs. Real-time inline RIP (raster image processing) capabilities onboard digital presses help to maximize press utilization, which in turn can help to reduce energy use while idle and lower the environmental impact per print.

Automatic monitoring and enhancement of production patterns can help converters save time, improve print operation efficiency, reduce downtime, and minimize print waste – contributing to a lower sustainability footprint for the overall operation.

Hardware automation

Combining pre-press, printing, and finishing in a single, automated hybrid label printing process can help to reduce power consumption as set-up times are shorter and job changeovers are more efficient. Continuous processes typically also use less material, as waste from overrun in each process step is eliminated, benefiting both the environment and the converter’s bottom line.

Conclusion

In the right scenario, digital printing technology can help converters and their brand customers establish more sustainable consumption and production patterns in line with wider sustainability commitments. Digital printing offers significant opportunities for limiting avoidable waste – including print-on-demand business models and late-stage customization.

Those switching to digital or augmenting analog printing processes with a digital printing module for their short-to-medium runs can expect to reduce waste and associated carbon emissions while increasing overall efficiency, making cost savings that positively impact profitability.

With over 60% of converters planning to invest in digital in the next 24 months, the time to act is now.

0 notes

Text

Looking for a trusted label supplier and manufacturer? Barspell Technology offers custom and pre-printed label solutions to businesses across the country. Discover high-quality, cost-effective labels tailored to your business needs.

0 notes

Text

Automatic Bottle Sticker Labeling Machine in Tanzania

Laxmi Pharma Equipment is a leading Manufacturer, Supplier, and Exporter of Automatic Bottle Sticker Labeling Machine in Tanzania. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. An Automatic Bottle Sticker Labeling Machine is a fully automated system designed to apply pre-printed labels onto cylindrical or round bottles. The machine automatically feeds, aligns, and applies stickers onto bottles with minimal human intervention. It can handle a wide range of bottle sizes and types, ensuring uniform application of labels for a polished and professional appearance. Laxmi Pharma Equipment's machines are built to meet the demands of industries where speed, quality, and accuracy are crucial for successful product labeling. Types of Automatic Bottle Sticker Labeling Machine: Single-Side Labeling Machine Double-Side Labeling Machine Round Bottle Labeling Machine Flat Bottle Labeling Machine Wrap-Around Labeling Machine Specifications: Labeling Speed: Up to 300 bottles/min Bottle Diameter: 20mm to 120mm Label Width: 10mm to 120mm Label Length: 15mm to 300mm Machine Dimensions: Customized based on model Power Supply: 220V, 50Hz Material: Stainless Steel (SS304/SS316) How fast can the Automatic Bottle Sticker Labeling Machine operate? The machine can label up to 300 bottles per minute, depending on the model and bottle size. Can the machine handle different bottle sizes? Yes, Laxmi Pharma Equipment’s machines can handle a wide range of bottle sizes, from small containers to large ones. What materials are compatible with the machine? The machine works with various bottle materials, including glass, plastic, and metal. Do you offer customization for specific needs? Yes, we provide tailored solutions based on your specific requirements, including label sizes, bottle types, and production capacity. Laxmi Pharma Equipment is an Exporter of Automatic Bottle Sticker Labeling Machine in Tanzania Including locations like Mwanza, Arusha, Dodoma, Mbeya, Morogoro, Tanga, Kahama, Tabora, Zanzibar City, Kigoma, Sumbawanga, Kasulu, Songea, Moshi, Musoma, Shinyanga, Iringa, Singida, Njombe, Bukoba, Kibaha, Mtwara, Mpanda, Tunduma, Makambako, Babati, Handeni, Lindi, Korogwe, Mafinga, Nansio. For more information, please feel free to contact us. https://www.youtube.com/watch?v=qVxO9PTcDR0&ab_channel=LaxmiPharmaEquipment Read the full article

#Ahmedabad#Arusha#AutomaticBottleStickerLabelingMachineinAhmedabad#AutomaticBottleStickerLabelingMachineinGujarat#AutomaticBottleStickerLabelingMachineinIndia#AutomaticBottleStickerLabelingMachineinTanzania#Babati#Bukoba#Dodoma#Exporter#ExporterofAutomaticBottleStickerLabelingMachine#Gujarat#Handeni#Iringa#Kahama#Kasulu#Kibaha#Kigoma#Korogwe#LaxmiPharmaEquipment#Lindi#Mafinga#Makambako#Manufacturer#ManufacturerofAutomaticBottleStickerLabelingMachine#Mbeya#Morogoro#Moshi#Mpanda#Mtwara

0 notes

Text

Boosting Efficiency and Minimizing Waste in Flexographic Printing: Effective Strategies and Solutions

Discover effective strategies to enhance efficiency and reduce waste in flexographic printing. Learn how to optimize your printing processes with actionable tips and best practices for improved output and cost savings. Boosting Efficiency and Minimizing Waste in Flexographic Printing Flexographic printing, commonly known as flexo, is a versatile and widely used printing method, particularly in packaging and labeling. However, inefficiencies in the process can lead to increased waste and higher production costs. By implementing targeted strategies, it is possible to significantly improve efficiency and reduce waste in flexographic printing. This article explores effective ways to achieve these goals. Understanding Flexographic Printing Flexographic printing involves using flexible plates to transfer ink onto various substrates, such as paper, plastic, and metal. It is praised for its speed, versatility, and ability to handle large print runs. Despite its advantages, the process can experience inefficiencies and waste without proper management. Strategies for Reducing Waste in Flexographic Printing - Optimize Ink Usage: Efficient ink management is crucial for reducing waste. Regularly monitor and adjust ink levels to ensure minimal wastage. Using low-viscosity inks can enhance print quality and reduce the need for reprints. - Regular Equipment Maintenance: Keeping printing equipment in excellent condition is essential. Regular maintenance and timely repairs prevent breakdowns and minimize downtime, leading to smoother operations and less waste. - Use High-Quality Materials: Investing in high-quality substrates and inks may have higher upfront costs but results in fewer defects and better overall print quality. This reduces the need for reprints and saves both time and resources. - Implement Process Control Systems: Advanced process control systems can monitor and adjust printing parameters in real-time. This helps maintain consistency and reduces the likelihood of errors that can lead to waste. - Training and Skill Development: Ensuring that operators are well-trained and up-to-date with the latest techniques and technologies can enhance efficiency. Skilled operators can quickly identify and address issues, reducing the chances of waste. Enhancing Efficiency in Flexographic Printing - Optimize Workflow: Streamlining the workflow from pre-press to post-press stages can improve overall efficiency. Implementing lean manufacturing principles, such as just-in-time production, can reduce unnecessary steps and speed up the process. - Automate Where Possible: Automation can significantly enhance productivity. Automated systems for plate mounting, ink mixing, and quality control can save time and reduce the potential for human error. - Standardize Procedures: Establishing standardized procedures for each stage of the printing process ensures consistency and minimizes variations that can lead to inefficiencies. Documenting best practices and creating checklists can be helpful. - Monitor Key Performance Indicators (KPIs): Regularly tracking KPIs such as press uptime, waste levels, and print quality helps identify areas for improvement. Data-driven decision-making can lead to targeted actions that enhance efficiency. - Collaborate with Suppliers: Working closely with suppliers to ensure timely delivery of materials and access to the latest technologies can improve the overall printing process. Strong supplier relationships can lead to better support and innovation. Conclusion By adopting these strategies, flexographic printing operations can become more efficient and produce less waste. Implementing regular maintenance, optimizing workflow, and investing in training are just a few ways to achieve significant improvements. Embracing these best practices not only boosts productivity but also contributes to a more sustainable and cost-effective printing process. Read the full article

0 notes

Text

Paint heal

Paint by number or painting by numbers kits are self-contained painting sets, designed to facilitate painting a pre-designed image. They generally include brushes, tubs of paint with numbered labels, and a canvas printed with borders and numbers. The user selects the color corresponding to one of the numbers and then uses it to fill in a delineated canvas section like a coloring book.

At Paintheal, we manufacture the best paint by number kits at a competitive price, thanks to our team's experience and licensing partnerships with artists and new talents.

We aim to improve people's lives through painting as a creative, relaxing, and fun activity, even for those without experience. We want you to put aside the stress of daily life to connect with your inner artist and enjoy that particular time just for you, without the limitations of gender, age, or training. Painting is for everyone, and we want to bring creativity to as many people as possible.

Welcome to China and visit our Factory.

Welcome To China And Visit Our Paint By Numbers Factory

1 note

·

View note

Text

Private Label Coffee

Your opportunity is here! Enjoy a quick R.O.I. in just 3-4 months and earn 100% to 300% profits monthly

QuickReturns #EntrepreneurGoals #FinancialSuccess #StartNow

If you are looking for a way to start your own healthy drinks business, we have done all the hard work for you.

Gonutrients Manufacturing HELPS Entrepreneurs and businesses start their OWN BRAND from START to FINISH

What healthy benefits do you want for your Coffee, Juice, Whey protein, Gummies, Choco or Capsule? Choices: Herbal, Slimming, Whitening, Anti-acne, Collagen or Anti-aging, Sleeping aid, Pre-workout, Creatine, Energy drink, Brain enhancer, Sunblock, Immune booster and a lot more..

.. Just let us know and our Chemist and R&D will do the rest

WHY 100-300% profit?

That's the "Mark-up" you can add based on our price since your direct to the manufacturer WHY 2-3 months Return of Investment?

- You can start PRE-SELLING online even before your products are delivered

How? Will HELP you with the following: Layout and design Product formulation via our R&D Printed sachets, boxes, and toll packing Assist in Halal, FDA LTO, and CPR

FREE Delivery within Metro Manila

Please check our video with Ms. Karen Davila on how we have HELPED more than 1,000+ clients locally and abroad MyPuhunan: Kaya mo! https://www.youtube.com/watch?v=Xn_BuaBVxh8&t=779s Our Awards: EEP World class Award: World-class service and products Achievements forum, Italy: Top 100 food manufacturer National customer choice award: Most innovative manufacturer Golden Globe: Best leading healthy products manufacturer Philippine top choice award: Top Wellness manufacturer Certification: ISO Certified Halal Accredited

Licensed FDA Food Manufacturer

Want more info? Call us NOW FREE CONSULTATION Tel: (02) 761-71002 Globe: (0917) 328-9558 Smart: (0998) 956-1689 www.gonutrients.ph FB Page: Gonutrients Manufacturing Youtube: Gonutrients Manufacturing

Gonutrients #Ownbrand #FoodManufacturer #Manufacturing

0 notes

Text

Mastering Legal Metrology Compliance for Medical Devices: Your Complete Guide

The manufacturing, sale, and distribution of medical devices are governed by strict regulations to ensure their safety and efficacy. Beyond registering devices with relevant authorities, manufacturers and importers must adhere to the Legal Metrology (Packaged Commodities) Rules, 2011. These rules are essential for maintaining transparency, protecting consumers, and fostering fair trade practices.

This guide unpacks the key provisions of Legal Metrology compliance and explains how adhering to these rules can enhance your business's credibility and operational efficiency.

What Are the Legal Metrology (Packaged Commodities) Rules, 2011?

The Legal Metrology (Packaged Commodities) Rules, 2011, established under the Legal Metrology Act, 2009, regulate the labeling and packaging of pre-packaged goods, including medical devices. These regulations ensure that consumers receive accurate, clear, and detailed information about the products they purchase. Compliance fosters consumer trust, prevents misleading claims, and upholds ethical business practices.

Key Provisions of Legal Metrology Rules

Labeling Requirements

Each packaged commodity must include a label with the following mandatory details:

Name and address of the manufacturer, packer, or importer.

Common or generic name of the product.

Net quantity in standard units (weight, measure, or number).

Manufacturing, pre-packing, or import date (month and year).

Retail sale price (MRP).

Dimensions or quantity of the commodity.

Display Panel Requirements

All declarations must appear on the principal display panel.

Information must be legible and prominent.

Net quantity and price should be printed in contrasting colors.

Labels must be in Hindi or English.

Wholesaler and Retailer Obligations

Wholesalers and retailers cannot sell, store, or display packaged commodities unless they meet all Legal Metrology provisions.

Retailers must not sell packaged products at prices exceeding the declared MRP.

Why Legal Metrology Compliance Matters

Fair Trade and Consumer Protection Transparent labeling ensures that consumers can make informed purchasing decisions.

Avoidance of Penalties Non-compliance can lead to fines, legal actions, or operational disruptions.

Market Transparency Accurate declarations enhance accountability and build consumer trust.

Efficient Inventory Management Compliance facilitates better inventory tracking and streamlined sales processes.

How to Obtain a Legal Metrology Packaged Commodities (LMPC) Certificate

To comply with the Legal Metrology Rules, manufacturers and importers must obtain an LMPC Certificate. Here’s the process:

Registration Apply under Rule 27 of the Legal Metrology (Packaged Commodities) Rules, 2011.

Document Submission Submit required documents, including business details, product information, and sample labels.

Review and Approval Authorities review the documents and grant the LMPC Certificate upon successful compliance.

Why Seek Expert Guidance for Legal Metrology Compliance?

Navigating the Legal Metrology certification process can be complex, involving technical and legal intricacies. Engaging a professional consultancy can save time, ensure compliance, and minimize errors, helping you focus on your core business.

How Regulatory Solutions Can Help

Regulatory Solutions has been a trusted partner for manufacturers and importers for over a decade, ensuring seamless compliance with regulatory frameworks, including the Legal Metrology (Packaged Commodities) Rules, 2011.

We offer:

Expertise in medical device, IVD, and cosmetic registrations.

A proven track record with a diverse range of products and categories.

Comprehensive support in obtaining the LMPC Certificate.

Ensure your products meet regulatory standards and build trust with your consumers. Contact us today to learn more about how we can support your compliance journey.

#legal metrology registration#legal metrology act#legal metrology rules#LPMC#Legal Metrology Packaged Commodities Rules

0 notes

Text

How an Automatic Sticker Labeling Machine Enhances Your Product Branding

Labeling is a significant part of packaging and branding, as it is the integral source of information attached to the product as well as serving conformity to standardization in different industries. An automatic sticker labeling machine ensures maximum efficiency, accuracy, and uniformity in applying labels on all products.

What is a Sticker Labeling Machine?

The sticker labeling machine is an advanced automated device that sticks pre-printed labels onto products or their packaging with an impressive degree of accuracy. Such machines cover a wide range of product sizes and shapes, thus being of great use in industries like food and beverage, pharmaceuticals, cosmetics, and manufacturing.

Types of Sticker Labeling Machines

Semi-Automatic Machines: Best suited for small to medium businesses, these machines combine manual setup with automated application to deliver flexibility and cost effectiveness.

Fully Automatic Machines: Accommodating bulk production environments, it is highly efficient and continued function with only a little input from human effort.

Custom Machines: Specialized equipment features designed for descriptive applications are customized to specific product needs.

Benefits of a Sticker Labeling Machine

High Efficiency: Automatic sticker labeling machine serve to the highest speed, thus, one can just imagine the time they can save for labeling large numbers at once boosting productivity while allowing deadline adherence.

Precision and Consistency: These machines make sure that the labeling has been uniformly applied and is free from misalignment, thus greatly enhancing the professionalism of your products.

Versatility: The sticker labeling machine can easily label products, whether cylindrical, flat, or in unique shapes.

Cost-Effective: Automating the labeling process reduces overheads in manual labor costs and waste of labels; it becomes quite economically viable for businesses in investing.

Applications of Automatic Sticker Labeling Machines

Replaceable Parts in Food and Beverage Industry: Cans, containers, and packages.

Pharmaceuticals: Accurate labeling of medicines and vials is made available.

Cosmetics: For tubes, bottles, and containers.

Industrial: Affixes informative labels onto tools, equipment, and components.

Features to Look for in a Sticker Labeling Machine

Automatic Adjustments: Adjustment according to different label dimensions and materials.

Durability: Withstand industrial environments.

Human-understandable interface: Simple to use with little training.

Adjustable configurations: Offers versatility to accommodate product lines.

Conclusion

Especially for those businesses that are concerned with packaging processes, an automatic sticker labeling machine is a must-have. It not only enhances productivity but also maintains brand equity and compliance. Be it for food, industry, or anything in between- invest in a sticker labeling machine for future growth.

Elevate your packaging game with Aim technologies advanced labeling technology today!

0 notes

Text

Pressure Sensitive Labels

Pressure Sensitive Labels

Pressure Sensitive Labels are pre gummed labels available in roll form to be used in a label applicator machine or applied by hand. There are many kinds of pressure sensitive labels such as paper, film, transparent (no look), speciality materials depending on the product and industry. Pressure Sensitive label is one of the most common product decorations for FMCG, Beverages, Spirits and Pharmaceutical industries. Pressure Sensitive labels can be applied on all types of plastic and metal containers, PET and Glass bottles, paper and laminated pouches. Roll Form Pressure Sensitive labels are manufactured in Flexo printing machines and for short quantities they are produced in Digital printing machines. Various embellishments such as spot coating, Hot foil, Embossing and thermo-reactive print are possible on pressure sensitive labels.

Types

Foil labels

No- look labels

Metallic labels

Color Changing labels

Double Side printed labels

Benefits of

Pressure Sensitive Labels

Highly decorative graphics are possible on these labels with multiple embellishments.

Clean finish of the applied labels on the bottle or jar. There are no excess gum leaking from poor application and the alignment of label to the bottle is straight on all the bottles.

No need to invest in complicated equipment to apply labels

No skilled operators needed to apply these labels and savings in man power costs involved in label application quality checks and correction

Numerous substrates options such as paper, plastic and clear films are available in these labels.

0 notes

Text

How a Potato Chips Packing Machine Enhances Efficiency and Quality in Snack Packaging

In the fast-paced snack food industry, packaging plays a crucial role in maintaining the freshness, quality, and shelf life of products like potato chips. The introduction of automated solutions such as the Potato Chips Packing Machine has revolutionized the way snack manufacturers package their products. These machines have become indispensable in modern production lines, offering speed, consistency, and cost-efficiency.

What is a Potato Chips Packing Machine?

A Potato Chips Packing Machine is an automated device designed specifically to package potato chips into bags or pouches. It is capable of handling various packaging formats, including pillow bags, standing pouches, and gusset bags, ensuring that the chips are securely packed without compromising their crispiness or freshness. The machine typically includes features such as portion control, sealing, labeling, and date printing.

Benefits of Using a Potato Chips Packing Machine

Speed and Efficiency One of the most significant advantages of using a Potato Chips Packing Machine is the increased speed and efficiency in the packing process. These machines can fill and seal multiple pouches per minute, reducing manual labor and increasing overall productivity. This allows manufacturers to meet high demand and maintain a constant supply.

Precise Portion Control With automated portion control systems, these packing machines ensure each pouch receives the correct amount of chips. This reduces waste, minimizes the chances of human error, and ensures consistency across all packed bags. This precision is vital for manufacturers who want to maintain the uniformity of their product and meet specific weight standards.

Enhanced Product Freshness The packaging process is critical to preserving the freshness and crispiness of potato chips. A high-quality Potato Chips Packing Machine uses advanced sealing technology that locks in freshness, protects the chips from moisture and air, and ensures that they stay crunchy for longer periods. This is particularly important in maintaining the snack’s shelf life and ensuring customer satisfaction.

Reduced Labor Costs By automating the packing process, manufacturers can significantly reduce the number of workers needed on the production line. The machine's high-speed capabilities enable the efficient use of time and resources, ultimately lowering labor costs while maintaining high output levels.

Customization Options Many modern Potato Chips Packing Machines offer a variety of customization options for packaging size, bag style, and branding. This flexibility allows manufacturers to cater to different market demands, from single-serving bags to large family-sized packs. Additionally, these machines can print production dates, batch numbers, and other essential information directly on the packaging.

Improved Hygiene and Safety Automated packing machines help to reduce the risk of contamination that can occur in manual packing processes. They are designed with hygiene in mind, featuring materials that are easy to clean and maintain. This ensures that the packaging process adheres to industry standards and regulations, reducing the risk of contamination and enhancing the overall safety of the product.

How Does a Potato Chips Packing Machine Work?

A typical Potato Chips Packing Machine consists of the following key components:

Feeding System: Chips are conveyed to the packing machine via an automatic feeding system. The chips are gently handled to avoid breaking or crushing during the transfer process.

Filling System: The chips are then accurately measured and dispensed into pre-formed pouches or bags. Depending on the machine, this could be done using a volumetric filler or a weight-based system.

Sealing: Once the chips are packed into the pouch, the machine seals the opening using heat or other sealing methods to ensure that the package is airtight and tamper-proof.

Labeling and Printing: The machine can print batch numbers, expiry dates, and other important product details on the bags, ensuring compliance with regulatory standards and adding branding elements.

Output: Finally, the packed bags are conveyed to the collection point, ready for distribution.

Types of Potato Chips Packing Machines

Vertical Form Fill Seal (VFFS) Machines These machines create pouches from a roll of film, fill them with chips, and then seal them. VFFS machines are highly versatile, making them suitable for different sizes and types of packaging.

Horizontal Form Fill Seal (HFFS) Machines HFFS machines operate similarly to VFFS but work horizontally. These machines are often used for larger packaging formats, such as family-sized bags of chips.

Automatic Pouch Filling Machines These machines are designed to fill pre-formed pouches with chips. They are commonly used in high-speed production environments where quick, efficient packing is essential.

Choosing the Right Potato Chips Packing Machine

When selecting a Potato Chips Packing Machine, manufacturers should consider factors like:

Production Capacity: Choose a machine that can handle the volume of your production line without compromising speed or quality.

Packaging Type: Ensure the machine is compatible with the packaging formats you need, such as stand-up pouches or pillow bags.

Customization: Consider machines that offer customization options, such as the ability to adjust portion sizes or print branding and production details.

Maintenance and Support: Choose a machine that is easy to maintain and comes with reliable technical support.

Conclusion

The Potato Chips Packing Machine is a game-changer for snack manufacturers looking to streamline their production lines while ensuring consistent quality and freshness. With benefits ranging from increased speed and efficiency to enhanced product hygiene and longer shelf life, investing in a high-quality packing machine is an essential step toward maintaining competitiveness in the snack food industry. For manufacturers aiming to stay ahead of the curve, automating the packing process with a Potato Chips Packing Machine is a smart choice.

For more information on how our Potato Chips Packing Machines can improve your packaging process, contact Munky Packaging Machines today!

1 note

·

View note

Text

Labelexpo South China 2024 opens – 4-6 December 2024

Momentum is building for Labelexpo South China, the only dedicated event in the region for the labels and package printing industry. The show is being held from 4-6 December 2024 at Shenzhen World Exhibition and Convention Center.

Over 180 exhibitors are taking part in this year’s show, including General Inkjet Printing, Arojet, HP, Jingle Blue, Youhua New Materials, Hengchengxiang, 3M, Jinya, Denchern Machinery, Yutian Machinery, Reborn, King Label and many more.

Day one features a panel discussion covering the impact and response to the restructuring of the global industry supply chain, presented by leading international label industry experts. Topics include the restructuring of the global label industry supply chain, changing consumer habits after the Covid-19 pandemic and the integration of AI technology into the label packaging industry.

The Digital Printing Forum on day one will cover topics such as technology trends, label industry market statistics, innovation through digital intelligence and pre-press process automation.

Also taking place is a Label Academy Workshop on Label Materials Technology focusing on the construction of self-adhesive laminates. The Workshop looks at face materials and liner materials, silicone coating technology, and designing adhesives for different end use applications.

Day two features a one-day training session looking into RAIN RFID encoding, hosted by the RAIN Alliance. Also, featured on day two are forums focusing on RFID smart label technology and anti-counterfeiting and traceability technology.

On day three, a hands-on social media forum takes place covering topics such creating a short promotional video, algorithm analysis, traffic acquisition and using AI for label design.

A Smart Label Trail will also be featured at the show, allowing visitors to discover first-hand what is new in the field of RFID technology. A range of suppliers will exhibit products, technologies, and services related to the entire process of RFID label manufacturing and usage.

Jade Grace, managing director, Labelexpo Global Series said, “RFID, digital and AI technology are making inroads in the Chinese label and package printing market. We look forward to highlighting this growing technology amongst other fast growing industry trends at the show this week.”

Kevin Liu, group director China, Labelexpo Global Series commented, “Labelexpo South China 2024 promises to be a show filled with educational content that will inspire and develop the skills of converters of all sizes in industry areas that are shaping the future of the label and package printing industry. I encourage all to participate in these valuable sessions.”

0 notes

Text

Industry trend|This nearly 20-year-old RFID company was acquired by a listed company

Multi-Color Corporation (MCC) was founded in 1985 and listed on the NASDAQ on August 28, 1987. It has 8,300 employees worldwide. MCC mainly produces and sells self-adhesive labels, serving the home and personal care, food and beverage, wine and spirits, and medical and health food packaging industries. MCC has new trademark pressure-sensitive, bonding, molding, shrink sleeve and cold migration technologies. In addition, MCC is also good at digital printing and provides a complete printing method including flexographic printing, lithography, gravure printing and digital printing, as well as internal pre-press services. MCC entered the Chinese market in 2011 and continues to serve existing multinational consumer brands.

MCC has factories and technical support in North America, Central and South America, Europe, Australia, New Zealand, South Africa and China, and can provide customers with global services. MCC also pays attention to environmental protection and sustainable development. The company uses environmentally friendly printing materials and production processes to reduce the impact on the environment.

Recently, MCC announced the acquisition of Starport Technologies, a smart label technology provider based in Kansas City, Missouri. The financial terms of the transaction were not disclosed.

Starport Technologies was founded in 2006 and has been focusing on the research and development and application of RFID technology since its inception. The company not only has strong R&D capabilities, but also has unique manufacturing processes that can meet the production needs of various surface materials, adhesives, RFID transponders, printing and other special coating rolls. This professional capability makes Starport Technologies highly competitive in the production and manufacturing of RFID tags.

Starport Technologies has a clear market positioning in the RFID industry, mainly serving consumer and supply chain applications. As major consumer products and retailers integrate smart label solutions, including RFID technology, into consumer and supply chain applications, Starport Technologies is in a stage of accelerated profitable growth. The company has won wide market recognition and customer trust with its professional RFID label products and services.

Starport Technologies has also achieved remarkable results in RFID technology innovation. For example, the company has developed a single-chip RFID reader IC for UHF mobile device applications. This reader has the advantages of wide range and low cost, providing a new solution for the application of RFID technology on mobile devices. In addition, Starport Technologies is constantly exploring and developing new RFID technologies and applications to meet the ever-changing market and customer needs.

This acquisition not only brings more resources and support to Starport Technologies, but also enables it to leverage MCC's global leadership to expand its marketing capabilities to meet the needs of customers in the United States and around the world. At the same time, the addition of Starport Technologies also provides MCC with more innovative technologies and features in RFID tags, which will help MCC continue to maintain close cooperation with customers.

Hassan Rmaile, CEO of MCC, said, “RFID is one of the fastest growing areas of MCC’s business and we are very pleased to welcome Starport and its expertise as an industry-leading RFID master label converter to the MCC family. Bringing our two high-performing teams together will allow us to continue to provide the industry with innovative, technical and functional RFID label solutions with exceptional service, quality and customer intimacy.”

Starport Technologies founder and CEO Jeff Nedblake and his staff will move to MCC to manage the newly formed Smart Packaging business unit of the combined company. “MCC’s core products, channel access, operational excellence and balance sheet make them the perfect partner from which we can expand our collective capabilities to meet the needs of our customers both in the U.S. and globally,” Nedblake concluded.

This paper is from Ulink Media, Shenzhen, China, the organizer of IOTE EXPO (IoT Expo in China)

0 notes